- Waxaad iibsan kartaa ama iibin kartaa saamiyada Beijing Jinyehong Metallurgical Machanical Equipment Corp.

- bjmmec@yeah.net

- +86 15201347740/+86 13121182715

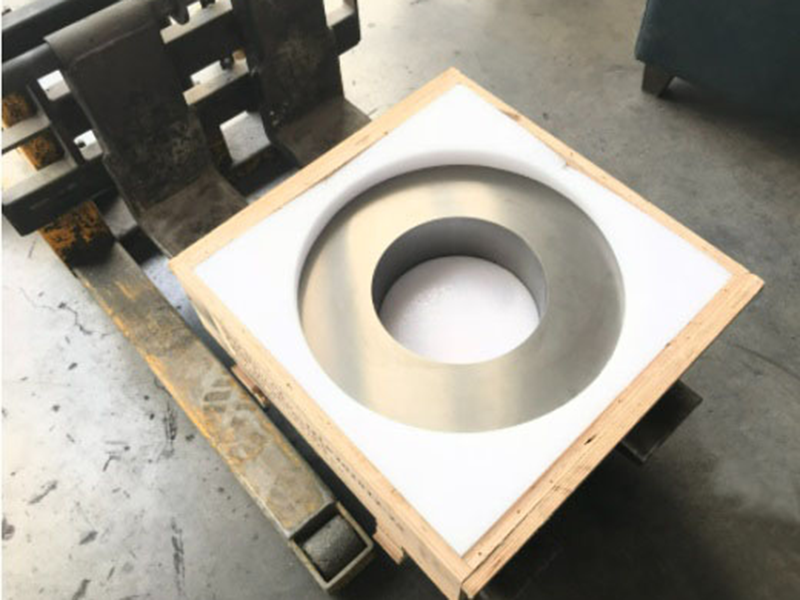

TC roll giraanti alaabada mashiinada duuban biraha

Hordhac Product

giraannada duubka carbide ee sibidhka ah (sidoo kale loo yaqaan tungsten carbide giraanta) ayaa leh hanti haynta kulaylka wanaagsan. Marka la barbar dhigo agabka kale, aad ayay uga wanaagsan tahay marka la eego kulaylka-iska-caabbinta,-iska-caabbinta iyo xoogga. Intaa waxaa dheer, engegnaantiisa wax yar ayaa hoos u dhigta heerka heerkulka sare. Sidaa darteed, siddo duudduuban carbide cemented waxaa la alifay la ap-pearance of xawaaraha sare ee ul siliga Mill.With horumarinta iyo hagaajinta, waxaa si balaadhan looga codsadaa in wax soo saarka ee silig xawaaraha sare, bar iyo bar birta qallafsan.

Ilaa iyo inta laga helayo alaabta alaabtayada, waxaa jira laba taxane sida Wc-Co iyo Wc-Co-Ni-Cr kuwaas oo leh sifooyin farsamo oo dhamaystiran. Xoog qalooca iyo adkaanta saameyntu waxay gaadhaan 2200 Mpa iyo (4-) x106J/ m' siday u kala horreeyaan Waqtigan xaadirka ah, mashiinka wax lagu dhammeeyo wuxuu guud ahaan ka kooban yahay 8-10 istaag. Sababtoo ah cabbirka weyn ee dusha jaban ee qaybta duuban, kuleejka ku yaal safka hore ee warshadda wax lagu dhammeeyo ayaa laga yaabaa inay iska caabiso waajibaad culus iyo saameyn xooggan. Sidaa darteed, adkaanta sare iyo caabbinta daalka kulaylka wanaagsan ayaa ah arrimaha aasaasiga ah, kuwaas oo ka hor inta aan la xirin-caabbinta. Iyadoo ay jiraan culeys yar iyo saameyn ku leh meelaha taagan, waa in aan fiiro gaar ah u siineynaa caabbinta xirashada iyo caabbinta kuleylka kuleylka ee duubista. faraanti Waqtigan xaadirka ah, mishiinka dhamaystirka guud ahaan wuxuu ka kooban yahay 8-10. Sababtoo ah xajmiga weyn ee dusha sare ee jabka ee qaybta duuban, koolada ku yaala dhinaca hore ee mashiinka dhamaystirka ayaa laga yaabaa inay iska caabiyaan waajibaad culus iyo saameyn xooggan. Sidaa darteed, adkaanta sare iyo caabbinta daalka kulaylka wanaagsan ayaa ah arrimaha aasaasiga ah, kuwaas oo ka hor inta aan la xidhin iska caabbinta. waa in aan fiiro gaar ah u yeelano caabbinta xirashada iyo iska caabinta daalka kulaylka ee giraangiraha duubka.

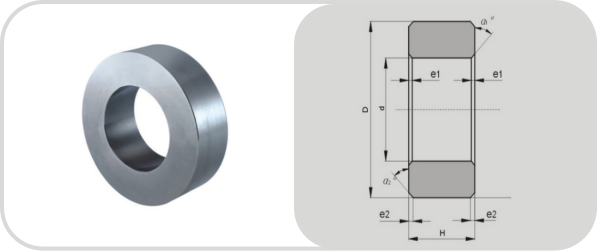

Sharaxaada Tc Ring

| Tirada OD(mm) | Xajmiga lD(mm) | Xajmiga dhererka (mm) |

| 145-450 | 87-280 | 62-150 |

duub carbide Tungsten

Baaxadda dhexroorka dibadda: 154-450mm

Baaxadda dhexroorka gudaha: 87-280mm

Baaxadda dhererka: 62-150mm

Shaxda Gaarka ah ee Rolls la dhammeeyay

| Dulqaadyada loo ogol yahay OD, ID, iyo Dhererka giraanta duubka (mm) | ||||

| NOOCA | OD≤200 mm | OD> 200mm | ||

| Darajo Wanaagsan | Fasalka caadiga ah | Darajo Wanaagsan | Fasalka caadiga ah | |

| Dulqaadka OD | ±0.020 | ± 0.050 | ±0.030 | ± 0.050 |

| Dulqaadka aqoonsiga | +0.020 | +0.035 | +0.025 | +0.050 |

| Dulqaadka H | ±0.025 | ± 0.100 | ± 0.050 | ± 0.100 |

| Fasalka ugu weyn ee TC birta shaabad giraanta farsamada oo leh cufnaan sare | ||||

| Darajo | Cufnaanta (g/cm³) | Hardness (HRA) | TRS(Mpa) | Codsiga lagu taliyay |

| YG4C | 15 | 89.5 | 1800 | Inta badan loo isticmaalo sida badhamada yar yar ee garaaca garaaca iyo sida galinta qashin-raadinta rotary si loo gooyo qaababka jilicsan, dhexdhexaadka ah. |

| YG6 | 15.8 | 89.5 | 1700 | Inta badan waxaa loo isticmaalaa sida badhamada qaniinyada garaaca yaryar iyo kuwa dhexdhexaadka ah iyo sida galinta qaniinyada rajada wareega si loo gooyo qaababka jilicsan, dhexdhexaadka ah. |

| YG8 | 14.7 | 88.5 | 2300 | Inta badan waxaa loo isticmaalaa sida badhamada qaniinyada garaaca yaryar iyo kuwa dhexdhexaadka ah iyo sida galinta qaniinyada rajada wareega si loo gooyo qaababka jilicsan, dhexdhexaadka ah. |

| YG13C | 14.3 | 86 | 2500 | Inta badan waxaa loo isticmaalaa sida gelinka iyo badhamada tricone bits rotary-percussive bits iyo dhagaxyada culus ee laylinta dhagaxyada si loo gooyo qaababka adag ee dhexdhexaadka ah iyo kuwa adag. |

| YG15 | 14 | 86.5 | 2500 | Way ka xoog badan tahay, waxaana inta badan loo istcimaalaa galinta iyo badhamada rotary-percussive bits, dhagaxyada culus ee laydhka si loo gooyo qaabab adag oo aad u adag.v |

Baakad & Gaadhsiin